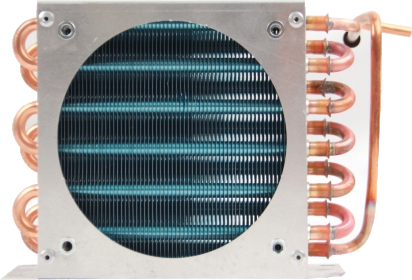

Chaoge manufactures finned block heat exchangers

for numerous civiland industrial applicaƟ ons where

heat transfer is required between airand primary

fluid such aswater, refrigerant gas, no-freezing

soluƟ on, etc.

Chaoge heat exchangers are produced with copper or

copper-nicheltubes and aluminum or copper fins.

Fins are provided with collars; the contact between

the tubes and the collars is obtained by mechanical

expansion of the tubes. Mechanical expansion of the

tubes provides a Ɵght bond between the fins and the

tube ensuring a high heat transfer between the

primary fluid and the air. Fins have a gauge collar that

providesan exact spacing between themselves.

Chaoge unique feature, each heat exchanger is cleaned

and degreased internally and externally, through liquid

and gaseous solvent washing,eliminaƟ ng even the

smallest parƟ cles.

AŌ er the brazing process, a leakage test is performed

on all the heat exchangers. In addiƟ on to the tradiƟ onal

test carried out with pressurizedair, keeping the heat

exchanger underwater, chaoge has an advancedtesƟ ng

system, which is used where possible. This test, carried

out withhelium as tracing gas, allows a high precision

level and the possibility toidenƟ fy also very small

leakages.